- HomeWelcome to HiTech

- AboutWho we are?

- ProductsProducts We Do

- Contact UsGet in Touch!

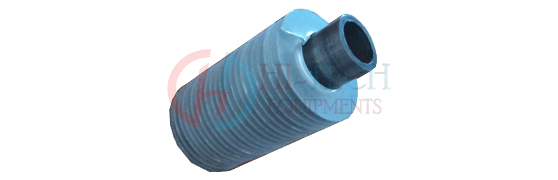

Finned tube heat exchangers which are designed as per the international standards and requirements of the clients. Finned tube heat exchangers can be employed for cooling or heating of air or other gases which flow in a duct or cooling of water and other liquids using air. Also, these units are provided with Aluminium extruded finned tubes. Finned tube heat exchangers are manufactured with copper, aluminum, stainless steel, admiralty brass, Cupro-nickel or carbon steel. Apart from this, these strongly constructed exchangers are widely used in different applications like air laden with abrasive particles, corrosive fluids and air heating with steam and designed for special custom-built applications.

We can manufacture a complete unit, replacement fin type coolers even a "parts kit"We replace existing fin us per customer request we do size likeLengthupto 20,000 mm,Weight up to 20 M.T ,Pressure up to 300 Kg/cm3 Temperature up to 1000°C, Tube Plate Dia upto 4000 mm, Thickness up to 100 mm. For a cross flow fin tube exchanger, the fins will typically be radial fins either circular or square, as shown in the pictures in this section. Most finned tube heat exchangers are cross flow, using finned tubes somewhat like the upper pictures. For a counter flow or parallel flow fin tube exchanger

1. New patented high-performance finned tube, pioneering technology.

2. Resists high loads, both thermally and mechanically.

3. Extremely dimensionally stable.

4. Hardly any maintenance is required – maximum reliability.

5. Optimised surface, less fans – clearly reduced energy consumption.

6. Less space required, less cabling – less installation effort.

7. Economically very profitable – saves labour, material and costs.

1. A great deal of water gets preserved on using Fin Type Cooler.

2. Less or no preparation needed as atmospheric air is in abundance.

3. No formation of scale or heat exchanger cleaning is required.

4. There are no mobile parts except for the fan and the motors. Hence the cooling tower maintenance is negligible.

5. Dust, fly ash, living organisms or dirt do not get mixed up with process water.

6. Reduced annual operating expenses.

7. No corrosions caused by air.

1. Predominantly used for air compressor and power generating units for applications of engine water cooling.

2. Processing of natural gas

3. Chemical Plants

4. Petrolium Refining

5. Plastic Machinery

6. Hydralic Power Packs

FRP Cooling Tower, Dry Cooling Tower, Wooden Cooling Tower etc..

Shell & Tube, Marine Cooled, Water Cooled, Finned Tube, Oil Cooled

Industrial Chiller, Air Cooled Scroll Chiller, Water Cooled Scroll Chiller

Fin Tube Coolers are produced in forced draught and induced draught designs.

Cooling Tower Fan, PVC Fills, Timber Structure Splash Bar etc..

FRP Chemical Tanks, Humidification Plant, Compressed Air Dryers, Radiators